|

I was staring out the window thinking about my old welding school days and learning about all the different types of corrosion and how they affect different substrates. I was staring out the window thinking about my old welding school days and learning about all the different types of corrosion and how they affect different substrates.

So many types of Corrosion….

• General or Uniform Corrosion

• Crevice Corrosion

• Stress-Corrosion Cracking

• Galvanic Corrosion

• Pitting Corrosion

• Intergranular Corrosion

• Microbiologically-Influenced Corrosion (MIC)

And the factors and mechanisms differ.

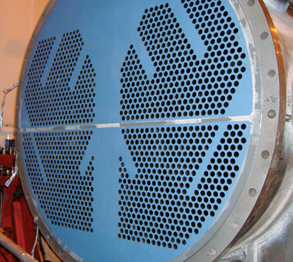

Heat exchangers are susceptible to erosion damage and galvanic corrosion due to contact between the dissimilar metals. When we leave this damage untreated, the operational efficiency of the system will be seriously undermined with the potential for complete deterioration of components. If the galvanic corrosion proceeds too long before it is addressed you can get a leak all the way through the tubesheet and the fluid on one side will mingle with the fluid on the other. This may not be a huge deal if both are water but usually one is refrigerant which might not be very good for the atmosphere or it could be a harmful chemical that should never be leaked. So, best case scenario is a huge loss of efficiency and capacity in the heat exchanger. Worst case scenarios include the release of radioactive steam and or catastrophic EPA fines.

Belzona offers a variety of epoxy materials for evaporators and heat exchangers damaged by the effects of erosion, corrosion, high temperatures and chemical attack. Our cold curing repair composites can be used to restore components such as tube sheets, flange faces, water boxes and end covers prone to erosion and corrosion damage, including galvanic corrosion.

Tell us, how can we help you repair, protect and improve your component equipment?

Stephanie Rumford

srumford@rumfordgroup.com

937-435-4650

RumfordGroup.com

|